Coal-producing regions are often plagued by long-burning mine fires. These fires burn underground and are typically difficult to extinguish due to the large scale, high temperatures and inaccessibility of the fires. The fires have numerous detrimental effects including emission of airborne toxins, subsidence, and greenhouse gas emission. In fact, coal fire emissions are estimated to account for 2-3% of global CO2 emissions from fossil fuel sources [1,2].

Despite the sustained negative impact of mine fires, they receive relatively little attention from the research community compared to more visible environmental catastrophes such as the 2010 Deepwater Horizon oil spill. Research is also hampered by the loss of knowledgeable academic coal geologists as coal falls out of favor as an energy source. The last newsletter of the Geological Society of America Energy Geology Division (formerly Coal Geology) largely laments falling membership numbers and participation in technical conferences [3].

This research was inspired by the recent DARPA Subterranean Challenge in which robots are tasked with exploring and traversing underground structures autonomously [4]. Could such robots operate within a mine fire? A number of potential issues may exist beyond what the "SubT" robots are expected to encounter. These issues include high-temperatures, borehole-only access, and debris unique to the mine fire environment - coal ash, for example. We hypothesize that these constraints represent surmountable engineering challenges.

Temperatures as high as 315C have been recorded at the surface above some mine fires [5]. However, a large selection of robot chassis materials is available that can comfortably exceed these temperatures. Electronics could be more problematic, but electronics are available for high-temperature aerospace applications. Additional techniques may involve integrating cooling systems within the robot.

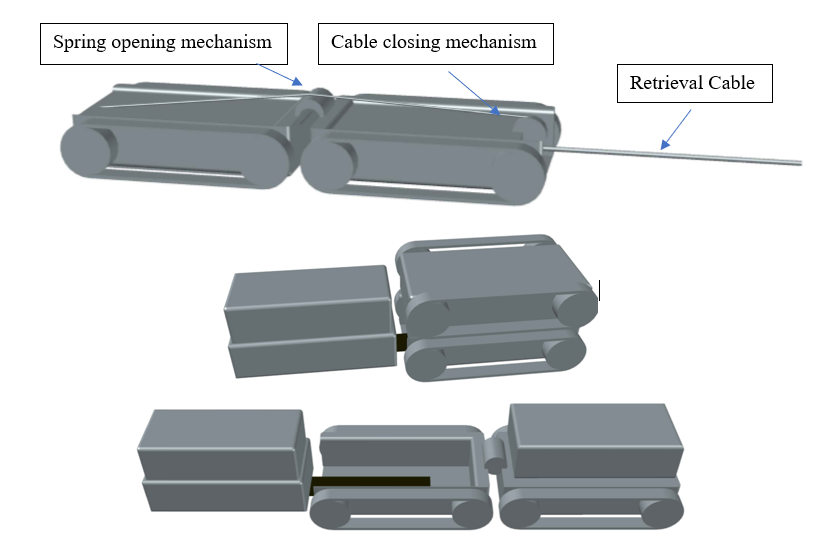

Mine fire access is more economical and convenient through existing narrow (typically 4-6" diameter) boreholes. These boreholes may have been drilled to monitor and access the fire during previous attempts to extinguish it. Robotic borehole access may be achieved by constructing a foldable chassis. In this model, the chassis will have two configurations - a slender folded configuration and a functional deployed configuration.

Debris may be a significant concern. This debris may consist of ash from previously burned coal in addition to collapsed material from layers overlying the coal. While this debris may impose constraints on robot design, a number of locomotion techniques are available which are suitable to a variety of terrains.

If it is possible to demonstrate operable robots within an active coal mine fire, a number of interesting research application may be enabled. Most significant of these would be next generation techniques for extinguishing fires - for example, using directly-applied high-expansion foams. However, it may also be possible to explore active mine fires for recoverable rare earth elements, and novel extremophiles.

Mine fire abatement has been approached historically with the assumption that the fire itself is inaccessible. So, existing techniques primarily rely on those that can be applied from the surface (such as inundation or excavation) [6]. With robots capable of withstanding mine fire conditions, a number of new possible abatement strategies may become feasible. These may include in-situ excavation or application of firefighting compounds.

Economically viable extraction of rare earth elements from coal ash is an area of significant research interest today [7]. If possible, it may help reduce U.S. reliance on foreign sources of rare earth elements for high-technology and defense applications. Coal ash samples from mine fires have not been previously studied and are of interest because of the different combustion and weathering conditions in a mine fire as opposed to a power generation station. These differing conditions may have an impact on the ease of extraction of rare earth elements.

Within the mine fire cavity, areas of intersection between the fire and groundwater are expected. While these pools may have some characteristics (low pH, dissolved minerals) similar to acid mine drainage sites which have been previously explored for extremophiles, they may be unique due to long-term high temperatures and exposure to non-atmospheric gasses.

The Laurel Run mine fire site was selected for initial study due to availability of existing boreholes and favorable geology. Based on conversations with local coal geologists, the site is expected to have a stable sedimentary layer overlying the fire and a relatively gentle slope. These characteristics should ease design of the first-generation rover.

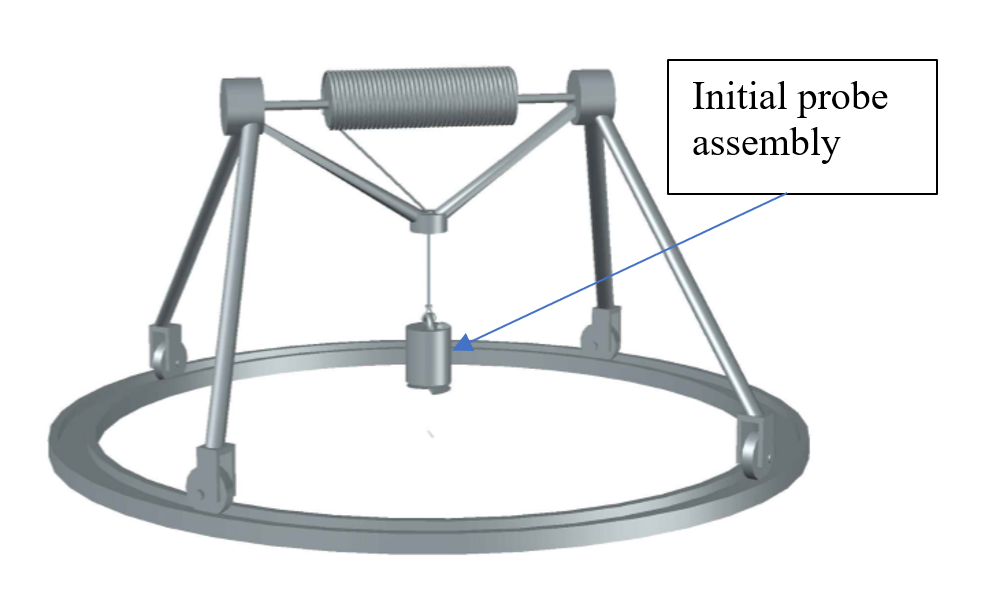

Once approval is granted by the State of Pennsylvania for site access, a borehole will be opened, and a probe inserted. The probe will collect data about temperatures and debris within the mine fire cavity. This data will aid in the design of the following stage.

The second stage system will take the form of a rover and base station which can communicate via RF. The rover will be fully mobile through the mine fire cavity. Additionally, it will include a modular system for attaching research instruments. For example, a video recording module may be attached for one descent and then replaced with an ash collection module during the next descent.